WHY ALLOY VS. TRADITIONAL BRICK OVENS

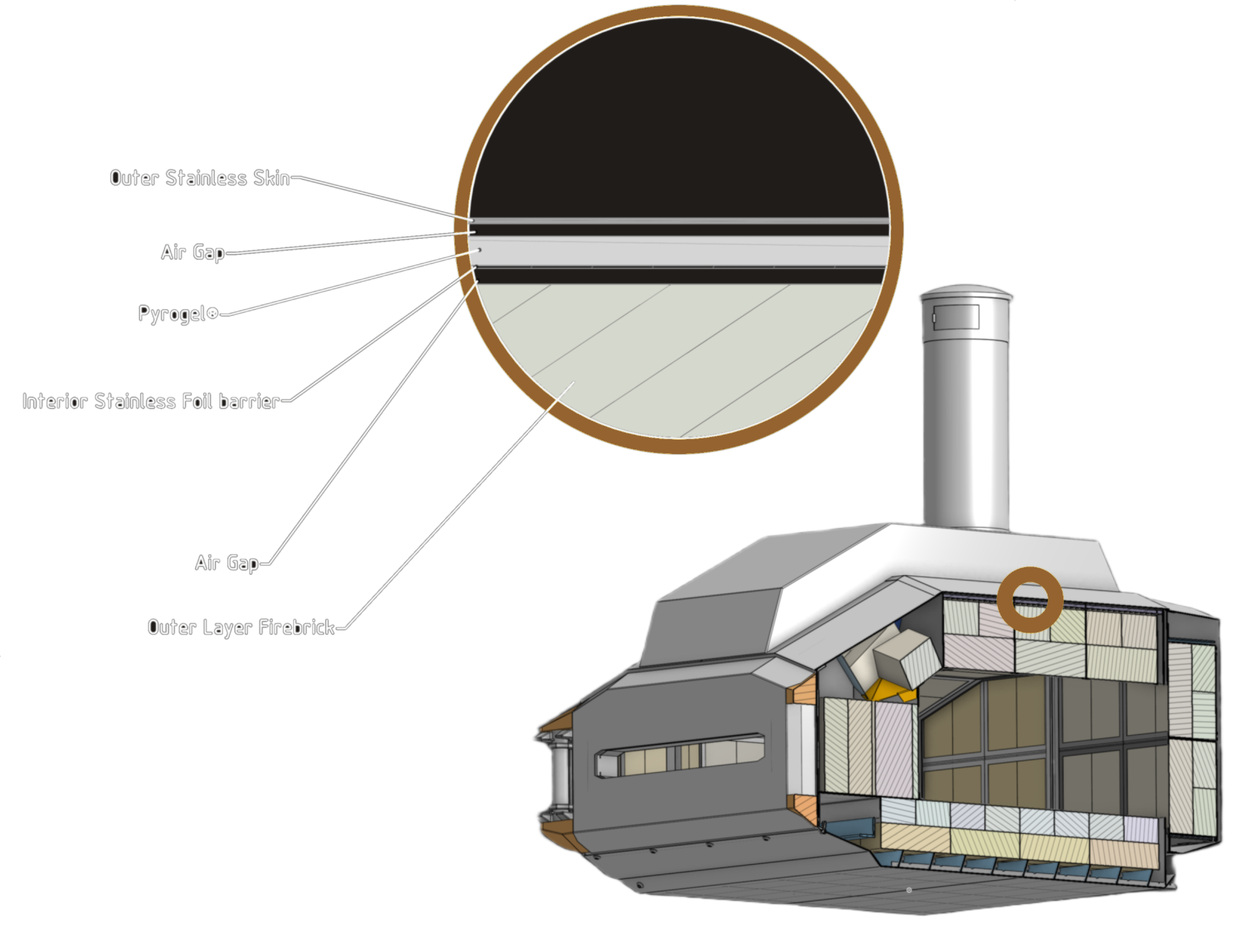

Patent-pending stainless rib-and-spar frame with replaceable brick cassettes. No mortar, no curing cycles, no vulnerability to over-firing or moisture. Fires reliably after rain or even flooding, without covers or special procedures.

MORTARLESS, MODULAR ARCHITECTURE.

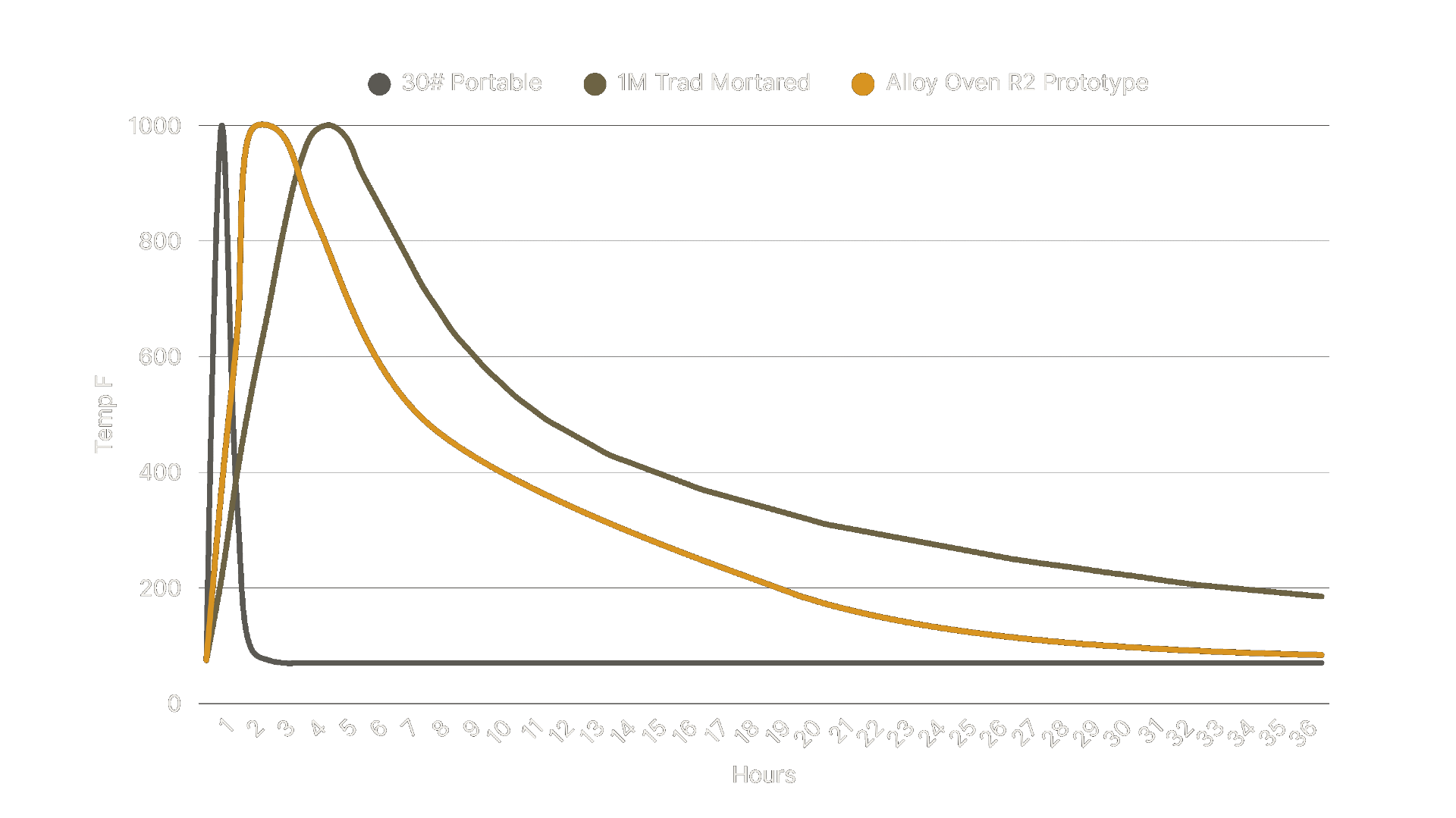

Mix brick densities and suppliers to balance heat-up speed with multi-hour retention. Optionally upgrade with space-age Pyrogel® insulation for unmatched thermal efficiency and safer exterior surfaces.

TUNABLE RETAINED-HEAT PERFORMANCE.

Wood & gas by default, with door-module options for charcoal, pellet, and even electric. Swap or combine fuels to match weeknight convenience or all-day wood-fired sessions.

INTERCHANGEABLE FUEL SYSTEMS.

Replace individual bricks or cassettes, not the oven. Modular construction and rear-door access reduce downtime and extend usable life for decades.

LIFETIME SERVICEABILITY.

True retained-heat performance without permanent construction. Assemble with basic tools, then relocate without demolition, cranes, or contractors.

TRANSPORTABLE AUTHENTICITY.

A front-origin duct flows over the dome to a rear insulated chimney, improving draft, settling embers, and keeping the outlet farther from the cook.

ENGINEERED EXHAUST PATH.

Sleek stainless form and engineered weather resistance. Crafted to elevate outdoor kitchens while withstanding rodents, freezing temperatures, and the elements.

REFINED, WARM-INDUSTRIAL DESIGN.

Traditional brick ovens reflect the limits of their era. Alloy preserves their authentic ratios and cooking performance, but applies modern engineering to deliver greater value, precision, and durability without the old constraints.